Week 4

Week 4 Reflection

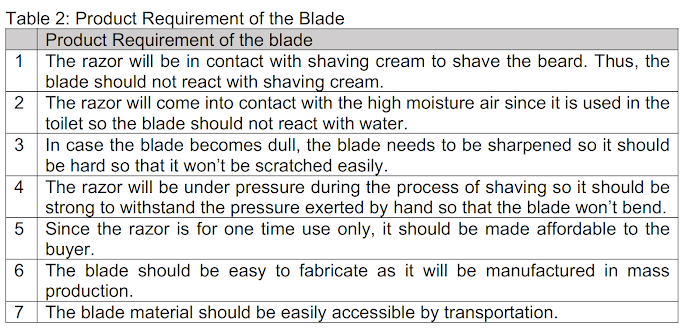

For Week 4, we did an assignment on material for design MFD which has been taught in Year 1 module CP5091. It is part of the designing stage where selection of material, shape and manufacturing process needs to be identified. For the selection of materials, a variety of components that meet the requirement of the product needs to be considered so that it is able to support the fabrication process while ensuring that the product can be used. For MFD assignment, our team is assigned to carry out material selection for a disposable safety razor for men. As such, we were tasked to find the best material for blade and body part of the razor. Below is the process of material selection.

MFD of Disposable Safety Razor

Material Selection for the Blade:

From the decision table above, it is shown that carbon steel obtained the lowest score of 180, so it is eliminated. Stainless steel 316 and stainless steel 304 are the 2 highest candidates with stainless steel 304 just slightly behind. Thus, further comparison between these 2 materials for the body will be based on the economic viability and ease of transportation.

Final Statement: The final options are between stainless steel 316 and stainless steel 304. By comparing the economics of the two materials, stainless steel 304 obtained a higher score of 300 because of cheaper material cost and higher machinability rating. Its value also lie in corrosion resistance and young modulus, the rest of the properties are considered decent. Therefore, stainless steel is chosen as the material to be used for the razor blade.

Material Selection for the Body:

Based on above description, these metals have been shortlisted as the material of the body part of the razor. The 3 possible candidates are silicone, polypropylene and polyurethane.

From the decision table above, it is shown that silicone has the lowest total score of 170, so it is eliminated. Polypropylene and polyurethane are the 2 highest candidates with polyurethane just slightly behind. Thus, further comparison between these 2 materials for the body will be based on the economic viability and ease of transportation.

Final Statement:

The final 2 options were Polypropylene and Polyurethane. Out of the 2 choices, polypropylene score is 3 times than that of polyurethane when it comes to economic reasons. Apart from economical reason, the criteria chosen for Polypropylene also has a higher score as compared to polyurethane. Its values lie in chemical reactivity with shaving cream, corrosion resistant to water, density and young’s modulus. Though its tensile strength is not the best, it still fulfils the requirement of not breaking under pressure. Overall, Polypropylene has a higher score than polyurethane, hence more suitable.

Reference

India, S., 2021. 316 stainless steel price per kg in India, SS 316 supplier. [online] Stindia.com. Available at: <https://www.stindia.com/316-stainless-steel-supplier.html> [Accessed 7 May 2021].

Geospacemfg.com. 2021. [online] Available at: <https://geospacemfg.com/blog/machining-304-316-stainless-steel/#:~:text=Grade%20316%20steel%20has%20a,most%20easily%20machined%20stainless%20steel.> [Accessed 7 May 2021].

Plastics Insight. 2021. Polyurethane Production, Pricing and Market Demand. [online] Available at: <https://www.plasticsinsight.com/resin-intelligence/resin-prices/polyurethane/> [Accessed 7 May 2021].

Matweb.com. 2021. Online Materials Information Resource - MatWeb. [online] Available at: <http://www.matweb.com/> [Accessed 7 May 2021].

Comments

Post a Comment